SECTION 07 90 05 - Epoxy Joint and Crack Filler (Product #11)

PART 1 - GENERAL

1.01 SUMMARY

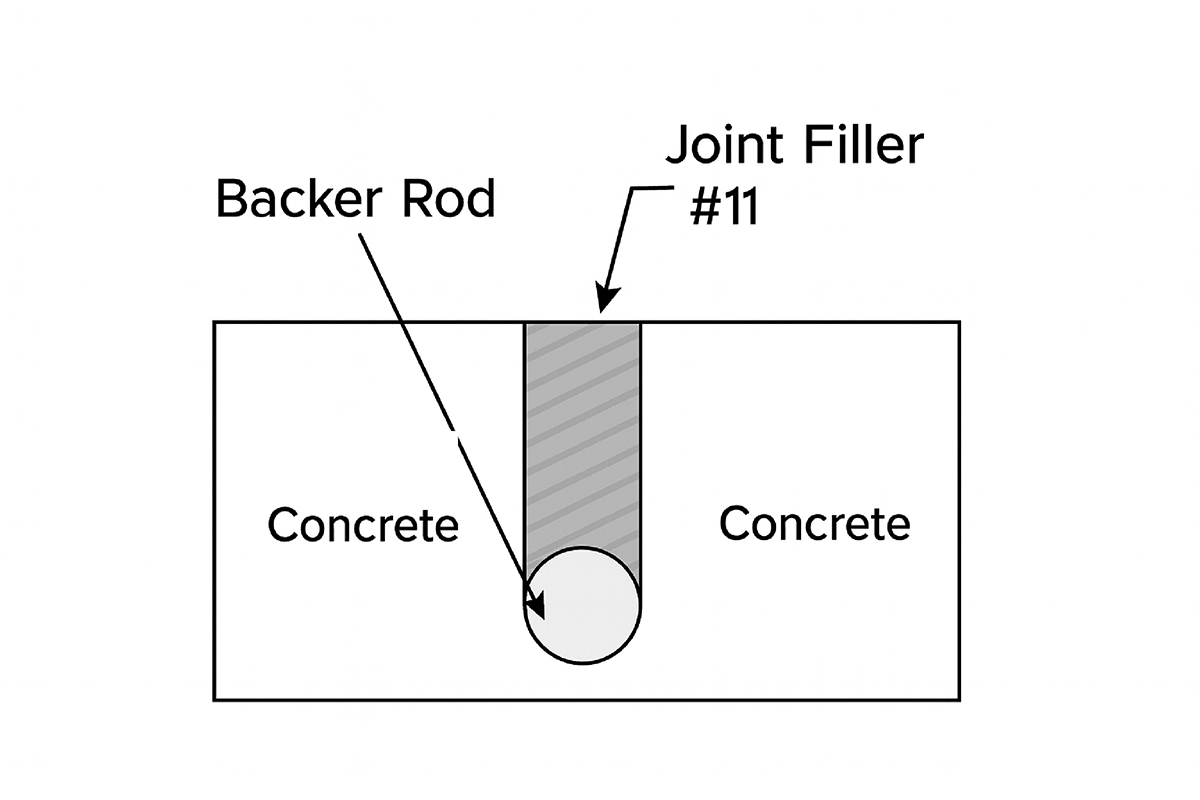

Provide all labor, materials, and equipment to install a 100% solids, zero (0) VOC epoxy joint filler for saw-cut control joints in concrete slabs on grade. Work includes surface preparation, backer rod installation, mixing, application, and finishing of Epoxy.com Product #11 Epoxy Joint Filler.

1.02 REFERENCES

1.03 SUBMITTALS

- Manufacturer's product data and Safety Data Sheet (SDS).

- Verification of installer experience for epoxy crack/joint repair.

1.04 QUALITY ASSURANCE

- Manufacturer: Epoxy Systems, Inc. - Dunnellon, Florida - www.epoxy.com - Technical Support: (352) 533-2167.

- Mock-Up: Provide a minimum 2 ft x 2 ft sample area showing backer rod installation and finished profile.

- All properties and installation requirements are per the manufacturer's published Technical Data Sheet, latest revision.

1.05 PROJECT CONDITIONS

- Concrete must be clean, sound, and dry.

- Substrate and air temperature shall be between 50 deg F and 90 deg F and at least 5 deg F above dew point.

- Protect from moisture, dust, and vibration during cure.

PART 2 - PRODUCTS

2.01 MANUFACTURER

Epoxy Systems, Inc.

Dunnellon, Florida, USA

Website: www.epoxy.com

Technical Support: (352) 533-2167

2.02 MATERIALS

A. Product: Epoxy.com Product #11 - Epoxy Joint Filler for Saw-Cut Control Joints.

- 100% solids, zero (0) VOC flexible epoxy resin for saw-cut and control joints in concrete slabs on grade.

- Mix Ratio: 1:1 by volume (Part A Resin to Part B Hardener).

- Colors: Light Gray or Dark Gray (standard).

- Packaging: 2-gallon and 10-gallon units.

B. Backer Rod: Closed-cell, non-gassing polyethylene foam sized 25-50% larger than joint width to prevent three-sided bond.

C. Hairline Cracks: Not for hairline cracks. Use Product #684LV MMA Crack Healer/Sealer per manufacturer instructions.

2.03 PHYSICAL AND APPLICATION PROPERTIES

| Property / Test Method | Result | Notes |

|---|

| Mix Ratio | 1:1 by Volume | Part A Resin to Part B Hardener |

| Viscosity (mixed) | approx. 2,200 CPS | Pourable liquid consistency |

| Gel Time @ 77 deg F | approx. 30 minutes | Depends on mass and temperature |

| Consistency | Pourable liquid | Self-leveling for horizontal joints |

| Initial Cure | 8 hours (80% strength) | At 77 deg F / 25 deg C |

| Final Cure | 2-3 days | Full mechanical properties |

| Shore A Hardness | 70-80 | ASTM D-2240 |

| Tensile Strength | 600 psi | ASTM D-638 |

| Ultimate Elongation | 35% | ASTM D-638 |

| Tear Resistance | 20 lb/in | ASTM D-624 |

| Service Temperature | 30 deg F to 180 deg F | Typical range |

| Artificial Weathering (ASTM G23-75 Type D) | 10-15% elastomeric property change after 1000 hrs | |

| Bond Cohesion after Water Immersion (Fed. Spec. TT-S-00227E) | No Failure after 25% total movement | |

| VOC Content | 0.0 g/L | Zero VOC - meets strictest Low-VOC standards |

2.04 MIXING

- Stir each component separately before blending.

- Mix one part by weight of Part A with one part by weight of Part B for three minutes with a low-speed drill motor equipped with a mixing paddle.

- Do not aerate mixture or overmix.

- Material temperature shall be 50 deg F or higher at time of mixing.

PART 3 - EXECUTION

3.01 SURFACE PREPARATION

- Prepare surfaces per Surface Preparation Guide.

- Remove all dirt, laitance, grease, curing compounds, and contaminants by sandblasting or mechanical abrasion.

- Blow out and vacuum clean joints immediately prior to installation.

- Ensure concrete is at least 28 days old or has completed primary shrinkage.

3.02 APPLICATION

- Insert backer rod into joint bottom to prevent three-sided bond and control depth.

- For flat surfaces, pour Product #11 directly into joint. For vertical or overhead surfaces, thicken with Epoxy.com Product #71 per manufacturer instructions.

- Apply using caulking gun, trowel, putty knife, or by pouring.

- Mask edges of joints where cosmetics are important. Remove masking immediately after tooling.

- Allow to cure per manufacturer's instructions before subjecting to traffic or load.

3.03 LIMITATIONS

- Do not thin with solvents; improper cure will result.

- Do not apply to new concrete until primary shrinkage has occurred (minimum 28 days).

- Minimum installation temperature: 50 deg F.

3.04 SAFETY PRECAUTIONS

Prolonged or repeated exposure may cause eye and skin irritation. If contact occurs, wash immediately and seek medical help. Use safety glasses with side shields and wear protective rubber gloves. Refer to Safety Data Sheet for complete safety information.

3.05 CLEANING

Clean tools and equipment before material gels using MEK, acetone, or lacquer solvent.

End of SECTION 07 90 05

Epoxy joint filler cross-section showing concrete slab, backer rod, and epoxy fill profile.

Epoxy joint filler cross-section showing concrete slab, backer rod, and epoxy fill profile.

|

|

Proper mixing and installation is critical to the optimal success of all products.

See

Installation Tips,

Techdata, &

MSDS for more details on our products.

Be sure to contact us with any questions and/or concerns that you have.

For more information please contact:

Epoxy.com

A Division of Epoxy Systems, Inc

A Vermont Corporation

USA

We have products that have passed the test of time as well as the best new Systems available today.

Since 1980 - 40 years of the highest quality products

Hours: 9AM-4PM Eastern Time (6AM-1PM Pacific Time)

Closed for lunch from 12Noon to 1PM

321-206-1833 Customer Service - Ordering and Order Status

Katey Lambert-Fontaine, VP - Chief Operations Officer

sales@epoxy.com

Technical Support

352-533-2167 Norm Lambert, President - Technical Support Director

info@epoxy.com

352-489-1666 Accounting and Administration

Debby Lambert, CEO, and CFO

Copyright © 1994-2025 (providing

online information about the right product for the right job for nearly 30 years) EPOXY.COM a

division of Epoxy Systems, Inc. -

Florida and Vermont. All rights reserved.

|

We accept MasterCard, Visa, American Express, Discover, or Wire Transfers.

|

|